Quick Machining Tip 9 Conventional and Climb Milling YouTube

#1 Quick questionWhen milling aluminum (6061), I can only get a nice surface finish by climb milling. If I mill conventionally, the chips seem to get embedded in the freshly milled surface and mess it up. Is this normal? I have tried lots of different speeds, feeds, depths of cut and still get the same result. Thanks for the help.

Climb Cut Vs Conventional Cut YouTube

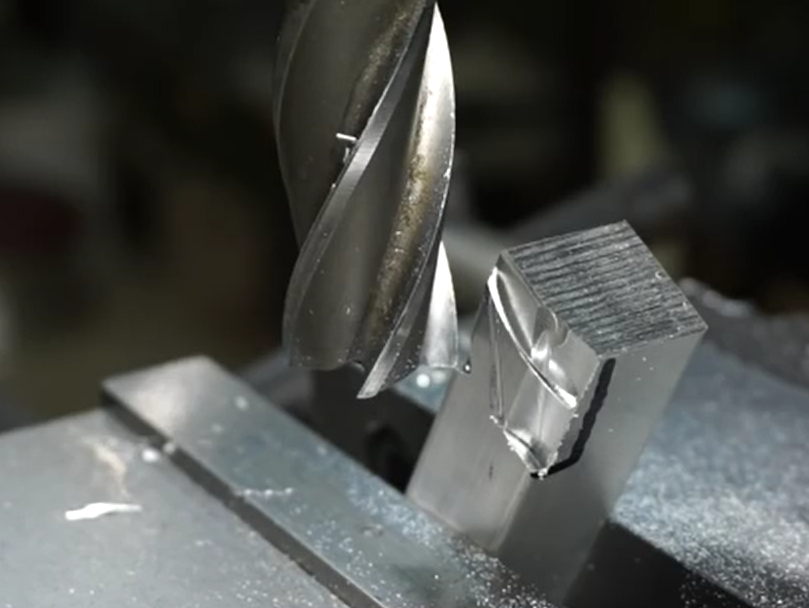

Climb milling also known as down mil. In this video, Mr. Kongable discusses the two different ways to move the cutter head on metal for a milling operation.

Tom's Techniques Climb Milling Vs. Conventional Milling

Check out our guide on climb and conventional milling, including the differences between climb and conventional milling, when to choose climb milling over conventional and the advantages of using climb milling for certain materials.

Conventional vs Climb milling steel on spongy DIY CNC YouTube

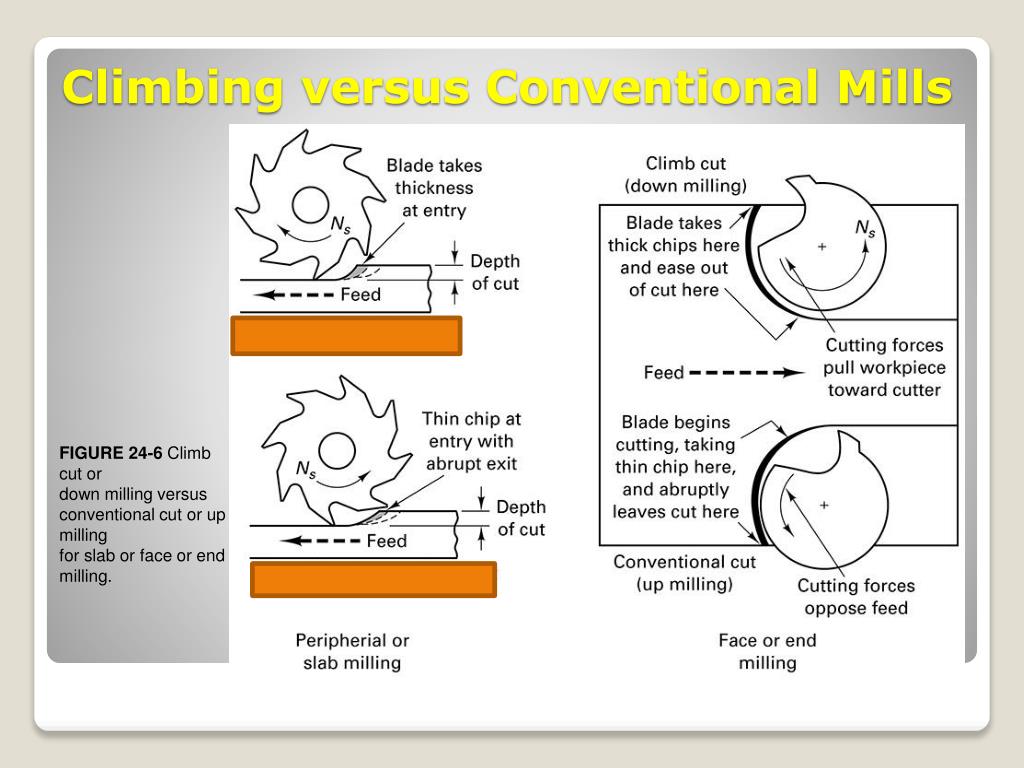

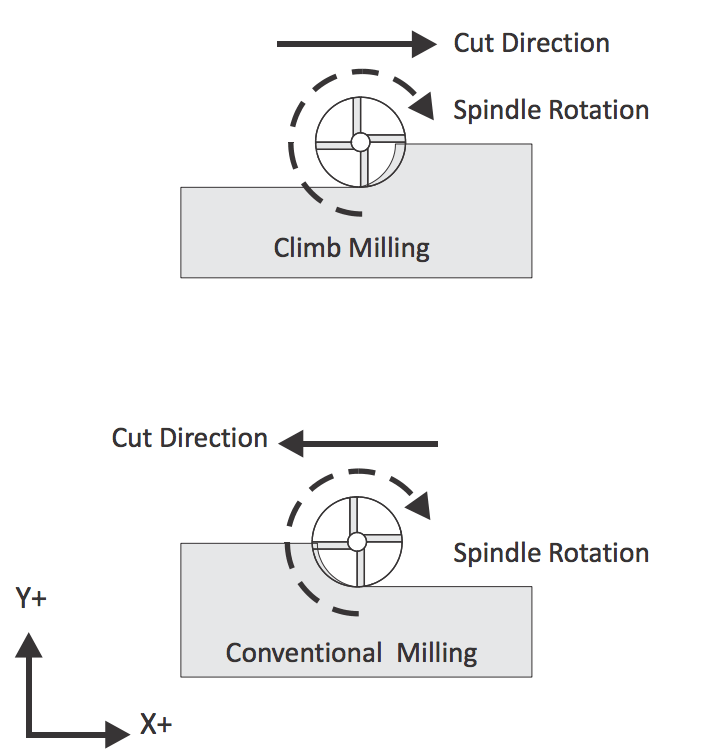

In Climb milling (also referred to as a down cut) the relationship between Spindle direction and Cut Feed direction combine in such a manner that the wide end of the chip is removed first and the narrow end removed last.

Climb vs Conventional milling slow motion! 5minFriday 9 YouTube

Climb vs. Conventional Milling Process Milling: Types of Milling Process (Climb Milling vs. Conventional) January 3, 2021 by Staff Milling is perhaps the most versatile metal machining operation. With today's multi-axis CNC milling machines, you can fabricate nearly any shape imaginable.

PPT Chapter 24 Milling (Review) EIN 3390 Manufacturing Processes Spring, 2012 PowerPoint

Climb milling addresses some of the downsides of conventional milling. Some key advantages include: Better surface finish Climb milling cuts away material in the same direction as the rotational movement of the milling tool. This results in less tool vibration and a superior surface finish compared to conventional milling. Increased tool life

Session 8 Climb Milling vs. Conventional Milling Dapra Milling Training YouTube

Conventional Milling (Up Milling) In conventional milling, the cutter rotates against the direction of the feed. As the workpiece is fed into the rotating cutter, the thickness of the chip starts at zero and increases, providing a safeguard against tool breakage. Climb Milling (Down Milling) In climb milling, the cutter rotates with the.

CLIMB MILLING vs CONVENTIONAL milling YouTube

Conventional milling is the traditional approach when cutting because the backlash, or the play between the lead screw and the nut in the machine table, is eliminated. Recently, however, climb milling has been recognized as the preferred way to approach a workpiece due to the fact that more and more machines compensate for backlash or have a.

Climb milling versus conventional milling what's the difference? PES Media

An explanation and demonstration of climb milling and conventional milling. Positive and negative points of each technique will be covered as well as example.

ComputerControlled Machining

Climb vs Conventional Milling: The Differences by Ofir Galiki Published Nov 11, 2021 Climb milling and conventional milling are two ways to machine a part. Learn the differences between them and when to use each. Climb milling and conventional milling are two ways to machine a part. Learn the differences between them and when to use each.

⭐ Climb o Conventional milling en CNC DIY LowPower.IO

Try the experiment on your mill of cutting both ways and you'll see that climb milling is a lot smoother and produces a better surface finish (most of the time, there are times when conventional milling gives a better finish, see below) than conventional milling.

Climb Milling vs. Conventional Milling DATRON Dynamics

Climb milling is when the direction of cut and rotation of the cutter combine to try to "suck" the mill up over (hence it's called "climb" milling) or away from the work. It produces the best surface finish. Here is a diagram showing climb versus conventional milling for a number of orientations: Arrows show workpiece motion, not spindle motion!

What is Milling? Climb vs. Conventional Milling Process

November 18, 2022 Milling is a form of subtractive manufacturing that involves cutting a stationary flat surface with a rotating tool. Climb and Conventional milling are the two main ways machinists use for milling a part. However, choosing between them is often challenging as both have merits and demerits.

Climb vs Conventional milling for CNC machining When to use each machining strategy YouTube

Climb Milling vs. Conventional Milling Roughing cuts and cutting hard materials should be done with "Conventional Milling." Finish cuts can be done with "Climb Milling." Climb milling is, as the name implies, the cutting edge of the tool that is literally climbing up the side of the part.

Conventional milling and climb milling Find suppliers, processes & material

Climb milling or down milling is a process where the CNC cutting tool rotates in the same direction as the workpiece. The name comes from the fact that the cutting tool's teeth climb onto the workpiece surface and deposit the chips behind the cutter, which eliminates the chances of recutting.

Bantam Tools Blog — Climb Milling with Bantam Tools Desktop CNC Machines

In climb milling, the cutting tool is fed in the direction of rotation. As long as the machine, fixture and workpiece allow, climb milling is always the preferred method. In edge climb milling, the chip thickness decreases from the beginning of the cut and eventually reaches zero at the end of the cut.